SBV/SBF12-16N3(I)(S)(R)(S) Series

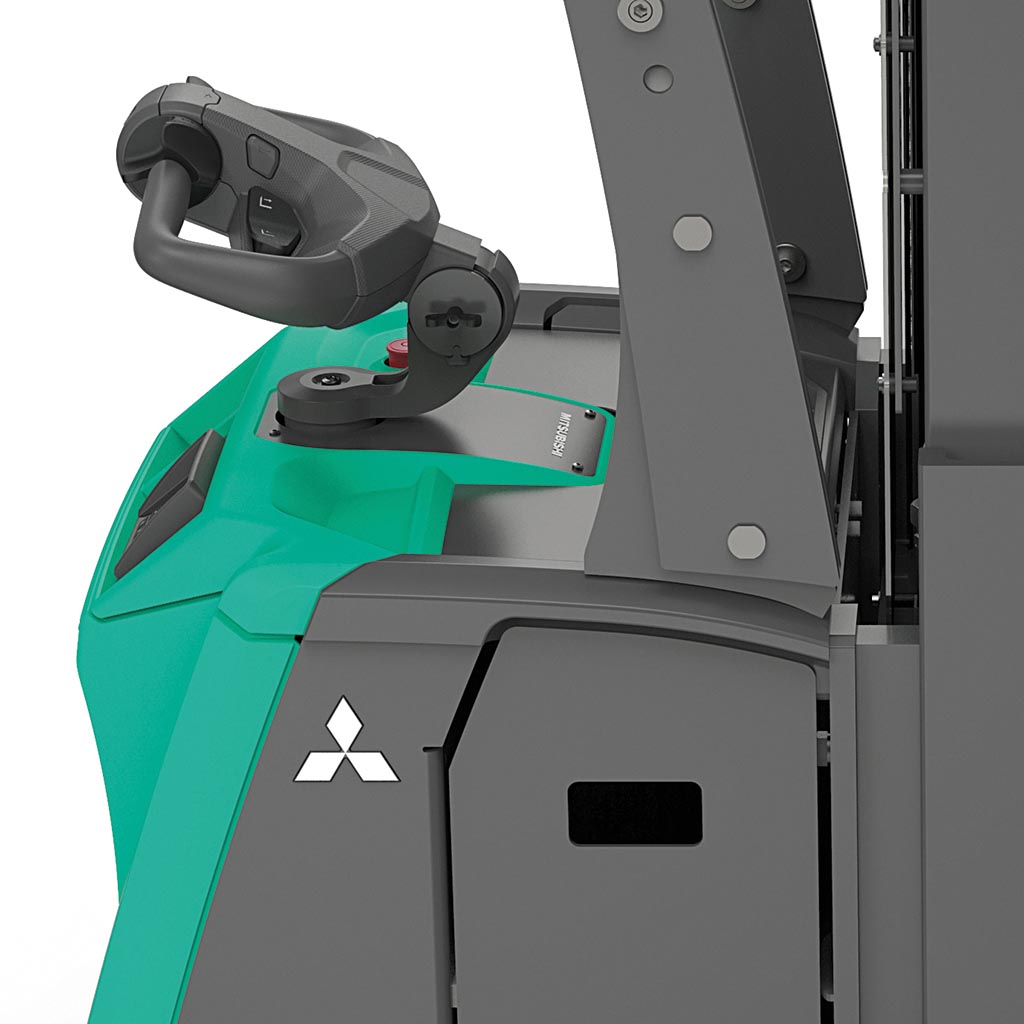

High performance Intuitive operation- Platform Stacker

- 1.25-1.60 Tonnes

- 24 Volts

- AC-Power

The compact and versatile AXiA EM 1.25 and 1.60 tonne platform stacker series is the perfect choice for high level stacking applications, order picking, and transport operations in narrow spaces.

The series is available in foldable platform models with optional sidebars for use in narrow spaces, fixed platform rear entry models for fast operations where maximum operator protection is required, and fixed platform side entry models for easy on-off access on both sides for picking applications. There are also wide straddle models available to allow greater flexibility in pallet handling, including closed and specialised carrier material. These models also enable the use of a variety of special handling attachments e.g. spikes, clamps, rolls, etc. AXiA EM has a sturdy 4-point chassis where the drive system is designed to increase traction and stabilisation proportional to the load. This keeps the truck consistently stable for safe, productive performance and confident operation.

Plus, a choice of modes (Easy, ECO & PRO) allows users of all skill levels to work to the best of their abilities. An extensive range of mast models are available with AXiA EM to ensure the truck is aptly suited to the application. Duplex masts offer lift heights from 2690 mm to 4200 mm, while Triplex masts deliver lift heights from 4350 mm to 5400 mm.

| Model | Capacity |

|---|---|

| SBF12N3IR | 1250 kg |

| SBF12N3IS | 1250 kg |

| SBF12N3R | 1250 kg |

| SBF12N3S | 1250 kg |

| SBF16N3IR | 1600 kg |

| SBF16N3IS | 1600 kg |

| SBF16N3R | 1600 kg |

| SBF16N3S | 1600 kg |

| SBF16N3SR | 1600 kg |

| SBF16N3SS | 1600 kg |

| SBV12N3 | 1250 kg |

| SBV12N3I | 1250 kg |

| SBV16N3 | 1600 kg |

| SBV16N3I | 1600 kg |

| SBV16N3S | 1600 kg |

Key Features

Compact chassis

The very compact chassis design allows the machine to work in much tighter aisles - releasing valuable storage space and making it safer to operate.

Choice of three operating modes (PRO, ECO and Easy)

Switchable modes set the truck's behaviours and performance to better match requirements for operator skill levels, performance and economy. Easy mode is aimed at less experienced drivers, ECO mode can extend the time between charges for maximum uptime, and PRO mode offers maximum available performance.

Ergonomic ErgoSteer tiller head

Class-leading, IP65-rated tiller head with large, easy-to-reach controls ergonomically placed for greater operating comfort and less fatigue through shifts.

Controlled Cornering System

Li-ion battery

Top Features

Controlled Cornering System

The truck senses both the velocity of the steering and the angle of a turn and reduces speed early for maximum stability and accurate, positive cornering.

Ergonomic ErgoSteer tiller head

Best-in-class, impact-resistant tiller head with large, easy-to-reach buttons placed at a patented ergonomic distance for reduced fatigue and safer operation. IP65 rated.

Adjustable EasyRide electric dampening

Unique electric damping capability allows operator to adjust the platform to their weight or preference - ideal for applications on ramps, uneven floors, and working over long distances. (Option on fixed platform trucks)

Choice of three operating modes (PRO, ECO and Easy)

Different driver modes: PRO for advanced drivers, ECO for low energy consumption, Easy for sensitive goods or beginners.

Damped platform

Foldable platforms and side/rear entry platforms are damped to ensure minimum vibrations and bumps for greater operator comfort. (All models)

More Features

High-efficiency regenerative braking

Some charge is regenerated back into the battery, and gives more effective control and reduces brake wear.

Powerful AC drive motor

Excellent traction, smooth, quiet, controlled operation, extended shift length and lower maintenance requirements.

Controlled Cornering System

The truck senses both the velocity of the steering and the angle of a turn and reduces speed early for maximum stability and accurate, positive cornering.

Large drive wheel

Increased radius extends the life of the wheel and reduces vibration on uneven surfaces for a more comfortable drive.

Combi controller lift system

Proportional rocker switch control for lifting and lowering.

Built-in Li-ion battery

Fast opportune charging removes the need for extra batteries and allows 24/7 operation. (Option)

Mounted battery plug

Plug is contained within a tray so there is no risk of loose cables getting caught when changing the battery.

Sealed electrical connectors

Sealed compartment prevents system failure and corrosion from water and dust.

Robust, tapered forks

Strong welded construction with pointed tips for effortless pallet entry. Access to pallets in racks or block stacks is easier, quicker and safer.

Initial Lift

This allows for better ground clearance on ramps, inclines, and uneven floors, and allows for double pallet handling. (I models only)

Wide Straddle Legs

Legs feature tandem wheels as standard. Straddle models have low profile forged forks. Open space allows a variety of specialised handling assemblies to be used. (Straddle models only)

Robust, clear view mast

Optimised design means excellent visibility of the forks and load.

Exceptionally smooth 'no knock' transition between mast stages

Vulkollan dampers ensure quieter movement over the lift range.

Load carrier stop in Initial Lift models

This enables quicker, easier, and safer alignment when double stacking pallets.

Smooth landing of the fork carriage

Hydraulic attenuation in the free-lift cylinder makes this much quieter.

Compact, robust chassis

Built for intensive operations, with great inherent strength and high residual capacities. Narrow and compact, the truck excels in small spaces.

Shared components in stackers and pallet trucks

Service costs and downtime are kept to a minimum and allows a more unified user experience for better familiarity and greater productivity.

High stability design

Traction, dampening and stability are all optimised to work in close harmony and produce unequalled drivability and stability - particularly beneficial when stacking.

Ergonomic ErgoSteer tiller head

Best-in-class, impact-resistant tiller head with large, easy-to-reach buttons placed at a patented ergonomic distance for reduced fatigue and safer operation. IP65 rated.

Conventional tiller arm

The standard mechanical steering option offers easy steering for low-intensity work. The design of the linkage system allows for a more compact, optimised arm than most stackers.

Power steering

Power steering allows for a short tiller arm with a reduced steering angle for comfortable, precise control and smooth cornering. (Option)

Pivot steering

Electric-powered steering without arm offers less operator fatigue in combination with the ergonomic platform. (Option)

Damped platform

Foldable platforms and side/rear entry platforms are damped to ensure minimum vibrations and bumps for greater operator comfort. (All models)

Adjustable EasyRide electric dampening

Unique electric damping capability allows operator to adjust the platform to their weight or preference - ideal for applications on ramps, uneven floors, and working over long distances. (Option on fixed platform trucks)

Foldable side bars

High, cushioned ergonomic side bars can be moved up or down and can be quickly switched to suit different operations. (Option)

Operator Presence Sensor

This locks all movement of the truck and its mast if the operator is not present.

Creep speed function and tiller-up drive

Both help to maximise safety and control in confined spaces. (Option on foldable platform trucks)

Choice of three operating modes (PRO, ECO and Easy)

Different driver modes: PRO for advanced drivers, ECO for low energy consumption, Easy for sensitive goods or beginners.

RapidAccess features

These allow quick and easy entry to all areas for checks and maintenance.

Storage compartment

Operator can store tools and other required items.

8.5 km/h drive speed, only with side bars or fixed platforms

Active Spin Reduction

Battery on steel rollers with bearings

OHG, standard for lift height ver 1790 mm with fixed platforms

Tiller up drive button

Cold store environment usage (-30 °C)

Different drive wheel options

Power steering (foldable platform model)

Load backrest

Multi-purpose tray

5 V USB power socket

12 V USB power socket

Equipment bar

RAM Holder. Size C or D

Writing desk

Choice of Li-ion or traditional lead-acid BS and DIN battery cell

Optional RAL colour

Features In Detail

Tried, tested and proven in the field, lead-acid batteries have been the long-standing choice for companies employing electric lift trucks. However, with long charging times, demanding maintenance requirements, the need for extra batteries, and high risk of operator misuse, it can be a challenge. Fortunately, there's a new battery system on the block: Li-ion from Mitsubishi Forklift Trucks.

Designed to meet your business' demands - including multi-shift (24/7) operations - without the need for spare batteries, our high-performance Li-ion battery system is up to 40 per cent more efficient than lead-acid counterparts. Plus, it's virtually error-proof, thanks to its ultra-low-maintenance design which prevent cell damage.

Features In Detail :

- Exceptional, zero-emissions efficiency - 40% more efficient than lead-acid batteries and free from gases.

- Ultra-low maintenance design - Just a full charge each week to activate cell balancing, as well as an annual CSV export/update.

- No space required - With no need for charging areas, there's no cost for set up and you can keep your profitable space just that: profitable.

- Quick charge capabilities - Just 15 minutes is all your battery needs to keep your truck going a few more hours. (It only takes 1 to 2 hours to fully charge a completely discharged battery.)

- Higher sustained voltage - This ensures more consistent lifting and driving performance, which is particularly noticeable towards the end of a shift.

- TriCOM Technology - Helps to deliver exceptionally high system efficiency (up to 97%)