Safety Features

A few of the key features across the truck rangeSmarter safety with smarter trucks

Not all trucks are created equal. And finding the right fleet has a huge impact on your workplace safety.

To best protect your employees, your site, your trucks, and your stock, you want the right tools for the job.

Because smart safety features can go a long way to encouraging operators to work safer. Something as simple as enforcing seatbelt use can mean the difference between an accident and a fatality.

Proper ergonomics means less strain on the driver through shifts, and reduced chance of RSIs and associated sick leave.

Because safety is not just about compliance; it's about fostering a culture of safety within the workplace.

By prioritising the well-being of employees, you can mitigate risks, minimise downtime, and ultimately, safeguard your most valuable assets.

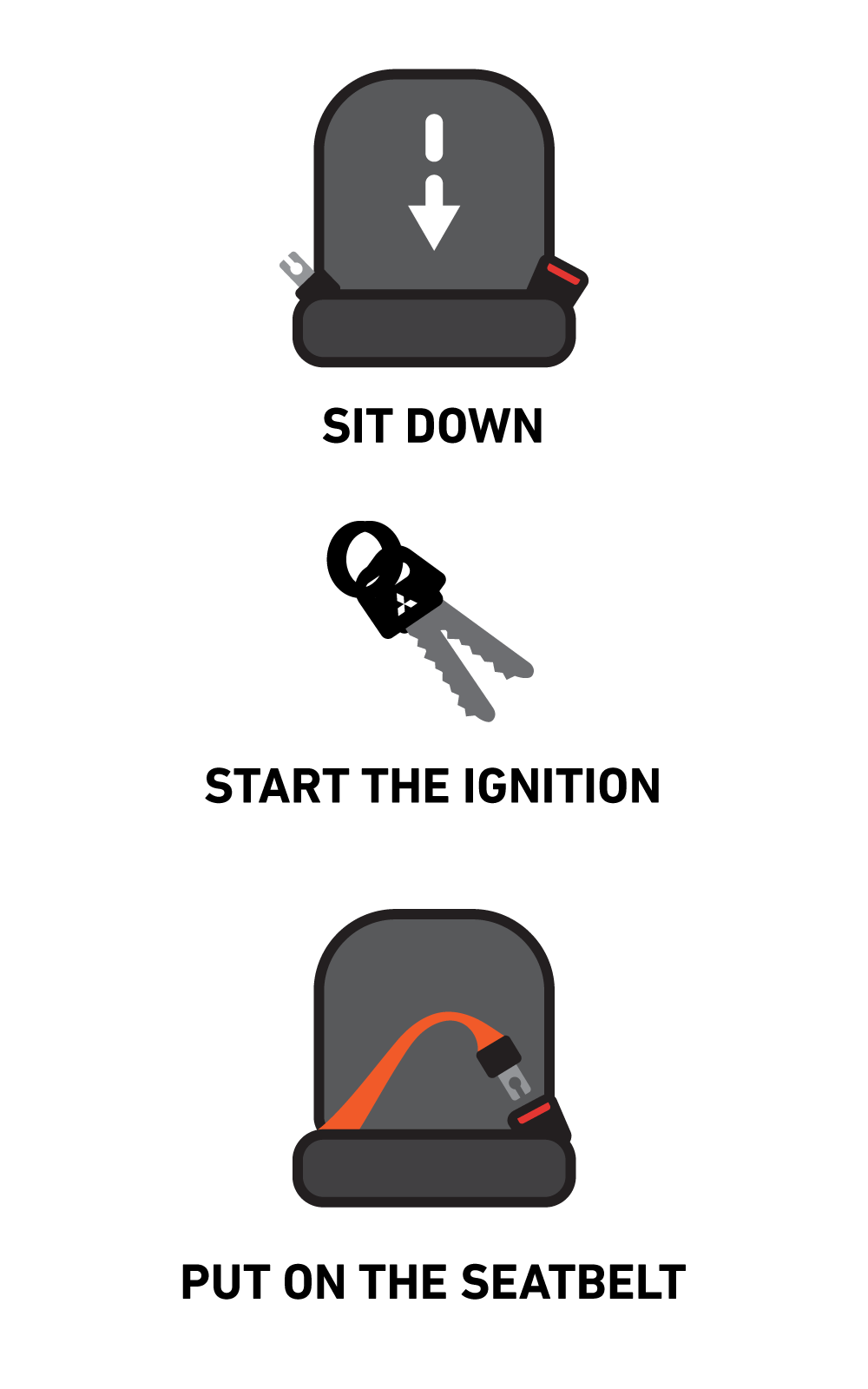

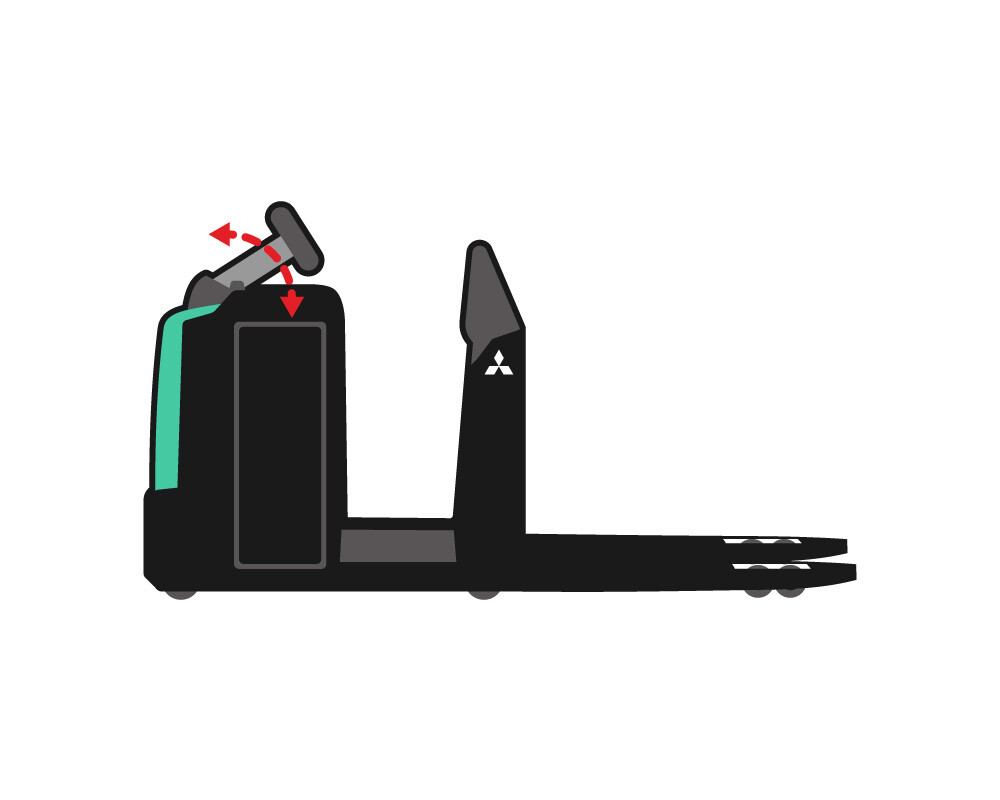

NO CHEAT SEAT BELT

Mitsubishi Forklift Trucks have been leading the way when it comes to operator and workplace safety and have aligned their trucks with the same vision.

For example, according to recent research, tipping accidents are the single most common cause of deaths among forklift operators (42%). In the large majority of cases, the driver was ‘mousetrapped’ between the truck and the ground, causing massive trauma to the head and upper body.

These accidents occur because when a forklift tips, the instinct of the driver is to jump clear — which generally isn’t possible. If the operator was to stay in place within the truck, they would likely walk away with only minor injuries.

Keeping them seated has proved to be a challenge... until now.

We have implemented the ‘no-cheat’ seatbelt on our electric forklifts and reach trucks.

This switchable option allows the employer to ensure wearing a seat belt is mandatory. If a simple sequence is not completed correctly the truck cannot be driven and the hydraulics will not function.

Sometimes the simplest things can make the biggest difference.

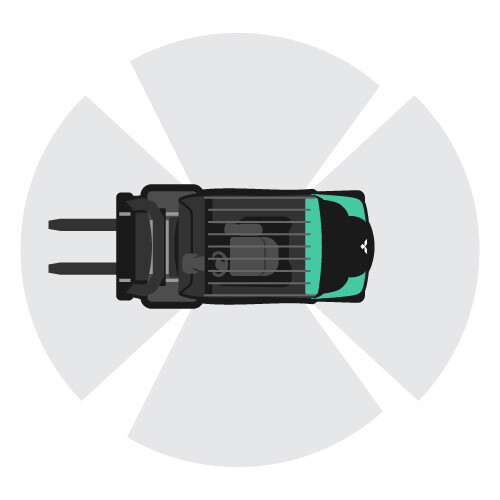

VISIBILITY

When it comes to the intelligence of the EDiA electric range, there has once again been an evolution in the safety department of the truck.

For example, the unrivalled 360-degree visibility is built with an optimised mast, wheel and dashboard all designed to maximise the visibility of the operator when it comes to lifting and dropping loads.

This ensures a safe, confident and productive operation in the tightest of spaces.

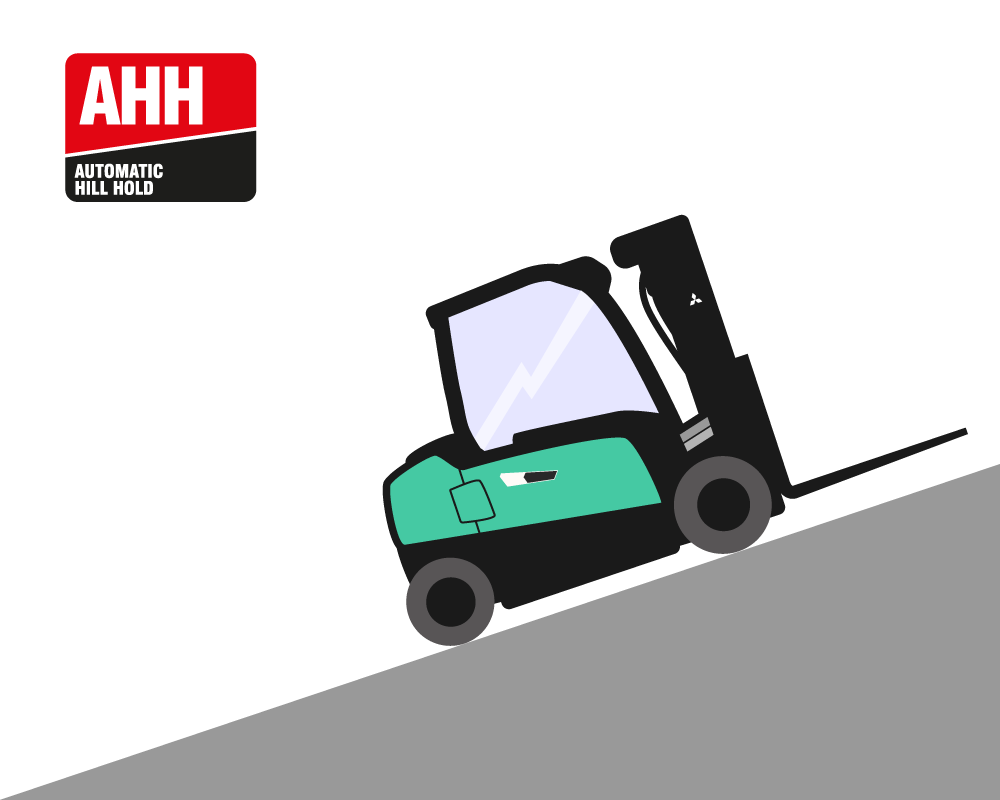

AUTOMATIC HILL HOLD

The game changing Automatic Hill Hold feature included in the EDiA and GRENDiA series prioritises both operator safety and productivity.

The truck stops automatically when the accelerator is not engaged, preventing rolling on ramps. As a result, there is no need to remember to use a handle or a switch.

This means the operator can remain focused on the task at hand without worrying about the truck rolling backwards and causing damage or injury.

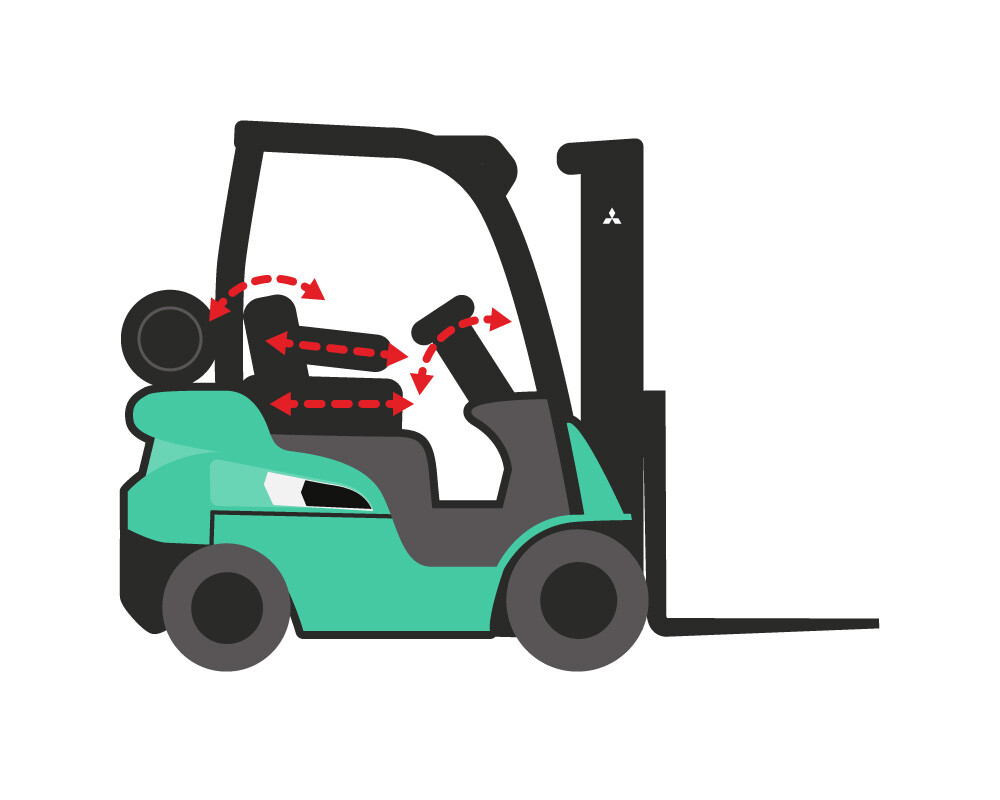

Adjustable operator compartments

It’s a fact that over the last few decades, people have been getting bigger, which includes forklift operators. But are forklift designers including this in their calculations? At Mitsubishi Forklift Trucks, the answer is yes.

Not only do cabins need to be larger, but they need to be genuinely supportive and adjustable in a range of ways. With models such as the EDiA EX and the SENSiA reach and multiway reach trucks, our designers carried out extensive research across the whole of Europe to deliver the highest ergocentric outcomes.

As a result, the operator compartments are the most spacious on the market and can be accessed via wide, low steps (essential for frequent on and off actions).

Our cabins ensure that drivers of every size are wholly contained within the truck itself — minimising the risk of limbs being trapped between the truck and racking.

With accommodation for a great range of body types, the suspension seats provide excellent back support and encourage good posture, ensuring operator comfort and productivity on every shift.

360-degree steering

Found on our reach trucks and 3-wheel EDiAs, this patented feature allows smooth turning without the 'pause' of a 3-point turn. It not only saves time in each and every turn — which adds up over the length of a shift — but puts less force on the load meaning it's less likely to wobble or fall. This makes for quicker, safer, and more stable operation.

Safety Zone

Safety Zone projects bright red lines of light onto the ground behind and to the sides of the truck. The result is a vivid 'no-go' area that pedestrians instinctively avoid, keeping them at a safe distance.

Unlike auditory warnings, which can be lost in noisy environments, Safety Zone delivers a clear, visual and unambiguous warning of a truck's presence — particularly valuable at the ends of aisles and at blind corners.

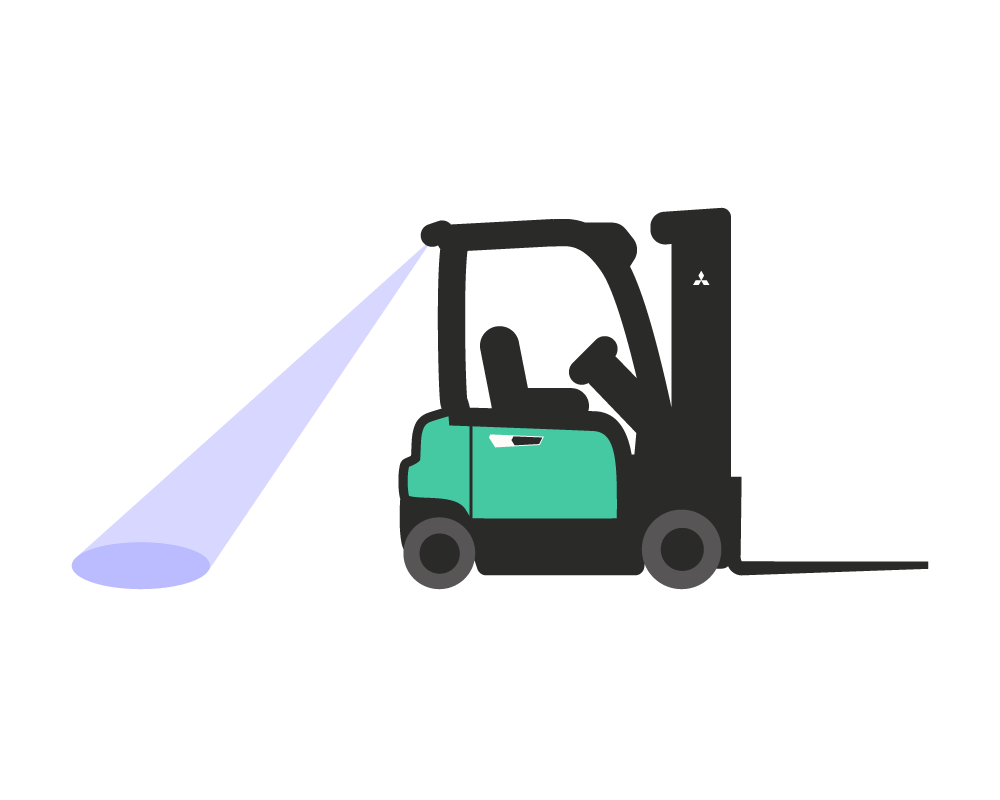

BLUE SPOT

Enhance workplace safety with the Blue Spot safety light. This feature projects a bright blue beam onto the floor, alerting pedestrians and other vehicles of an approaching forklift.

Designed for optimal visibility in any lighting condition, it significantly reduces the risk of accidents. Built to last, this durable and reliable light is easy to install and maintain, providing an effective safety solution for any industrial environment.

Need to review your forklift safety features?